Structural Composition

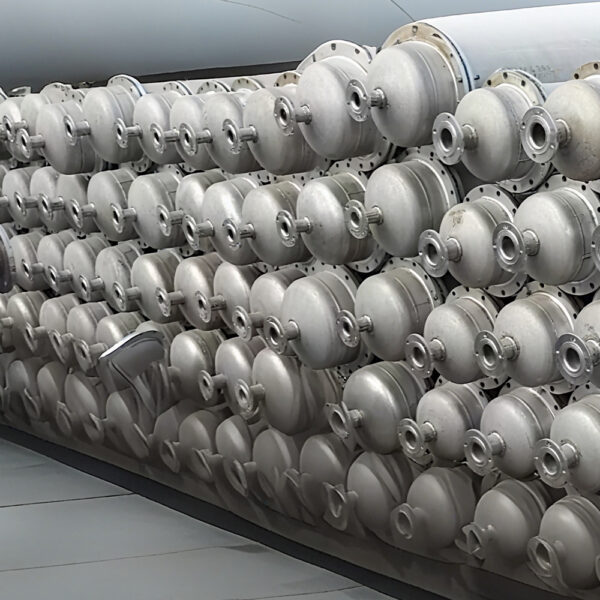

Mixing cylinder: Composed of two asymmetric cylinders formed by rolling and tightly welding high-quality stainless steel plates, with elliptical heads at both ends. The inner and outer walls are precision-ground and polished, with no dead corners and easy to clean.

Transmission system: Composed of a motor, reducer, sprocket chain, bearings, transmission shaft, etc. The transmission shaft is fixedly welded to the cylinder wall with reinforcing steel plates, ensuring no vibration, no eccentricity, and stable operation during work.

Rack: Made of channel steel through welding, with firm welding. It is covered with stainless steel plates, featuring a flat surface. Both ends of the transmission rack are equipped with movable doors for easy maintenance and repair.

Feeding port and discharging port: The feeding port is a movable cover plate, pressed tightly by a lever, and sealed with food-grade silicone rubber sealing strips; the discharging port uses a stainless steel butterfly valve, which has a good sealing effect and is easy to operate.

Working Principle

The V-type mixer drives the reducer through a motor, and the reducer then drives the V-type barrel to rotate via a coupling. When the V-type barrel rotates, the materials repeatedly undergo a “dispersion – convergence” cycle due to the action of gravity. When the V-shaped connection rotates to the upper position, the materials split and flow to the ends of the two barrels; when the V-shaped connection rotates to the lower position, the materials in the two barrels converge again at the center. At the same time, the materials also have movement modes such as convective mixing, shear mixing, and diffusion mixing, causing the materials to continuously undergo dislocation translation and forced convection in the V-shaped space, thereby achieving uniform mixing.

Characteristics

High mixing uniformity: Adopting a structure of two semi-cylinders with different lengths, there is a time difference in the flow of materials inside the cylinders, resulting in high mixing efficiency, with a uniformity of over 99%.

No cross-contamination: There are no dead corners in the contact parts between the inside of the cylinder and the materials. The mixing process is gentle without segregation, and the discharge is complete with no residue, thus avoiding cross-contamination.

Long service life: Made of stainless steel, it is rust-proof and corrosion-resistant, stable and durable.

Easy operation: Compact structure, small footprint, equipped with an automatic timing device, which can set the mixing time, automatically shut down at a fixed time, and facilitate feeding and discharging.

Application fields

It is suitable for mixing powders and granules with good material fluidity and small differences in physical properties, as well as for mixing materials that have low requirements for mixing degree but require short mixing time. It is also applicable to the mixing of granular materials that are easy to break and wear, or finer powders, blocks, and materials containing a certain amount of moisture. It is widely used in industries such as pharmaceuticals, chemicals, food, feed, ceramics, and metallurgy.